lilsam

10+ Year Contributor

- 145

- 1

- Sep 28, 2011

-

Milwaukee,

Wisconsin

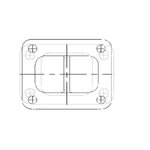

Provided everything else is up to the task, a Super/Pro 40 with a big divided hotside would be the ticket.

I know of at least one person has made ~680awhp on it with a smaller, more restrictive turbine housing, but those results are atypical.

So far at least.

But its a 70lb/min wheel. Open up the intake and exhaust, get a beefy cam, good fuel and let her eat.

What Holset would get me 70lb a min. I had a venom drag smim. Kelford 272s dual intank Wally 255s an 2150s?

)

) till then i'm saving what money i get

till then i'm saving what money i get