T9S1i

15+ Year Contributor

- 1,869

- 9

- Dec 16, 2004

-

San Francisco,

California

sounds great!!!

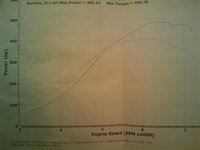

Good luck friday and dont forget us here on the forums!! We want pics, video, dyno plots everything!!! haha

Good luck friday and dont forget us here on the forums!! We want pics, video, dyno plots everything!!! haha

I have just recently upgraded a few things on my setup. I am running straight e85 I upgraded the injector from 880cc to 1200cc. I upgraded my from mount intercooler to larger one so i will be ready for dyno in a couple weeks

I have just recently upgraded a few things on my setup. I am running straight e85 I upgraded the injector from 880cc to 1200cc. I upgraded my from mount intercooler to larger one so i will be ready for dyno in a couple weeks here is my latest log with old setup and boost set @25psi

here is my latest log with old setup and boost set @25psi ! Oh by the way They used a steel piano wire not copper!

! Oh by the way They used a steel piano wire not copper!

). At 32psi stock motors with arps and mitsu mls. Push no coolant, and trap 129mph but my timing is at 12deg peak geeze wish I had e85 however I'm sure it could take more timing with the meth. Ran an 11.1 so far, going to run some 100 octane leaded fuel with the meth and a few more psi and more timing get this thing well into 10s on the stock motor before I drop in the built motor with the t4 s366 and spray.. Still going to run mitsu mls hg with copper spray standard arps at 105ft/lbs and shoot for 750awhp and some mid 9s. I don't believe you need to oring the block or use L19s for this.

). At 32psi stock motors with arps and mitsu mls. Push no coolant, and trap 129mph but my timing is at 12deg peak geeze wish I had e85 however I'm sure it could take more timing with the meth. Ran an 11.1 so far, going to run some 100 octane leaded fuel with the meth and a few more psi and more timing get this thing well into 10s on the stock motor before I drop in the built motor with the t4 s366 and spray.. Still going to run mitsu mls hg with copper spray standard arps at 105ft/lbs and shoot for 750awhp and some mid 9s. I don't believe you need to oring the block or use L19s for this.

Are you interested in selling you old bc 272?

Are you interested in selling you old bc 272?