XMasta19

15+ Year Contributor

- 1,309

- 21

- Jul 22, 2004

-

The "O",

Florida

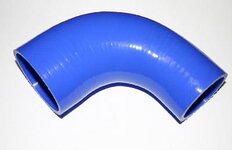

You can either use the links I already gave you with multiple bends and straight pipes, or do like me and get one with a bunch of 90's only.

http://cgi.ebay.com/ebaymotors/2-5-...043760660QQcategoryZ38634QQrdZ1QQcmdZViewItem

http://cgi.ebay.com/ebaymotors/2-5-...043765381QQcategoryZ33742QQrdZ1QQcmdZViewItem

I also had to get a 2-2.5" elbow reducer for the turbo compressor outlet.

http://www.machv.com/elco.html

I ended up also buying 2 red silicone couplers and some clamps from ATP for the sides of my FMIC. You can do it all with just 90's, you'll have to get one more though for coming off of the throttle body, unless you have a 2.5" bend from an intake like I did.

What exactly are you confused about when it comes to the oil lines?

Here is link to one of my threads, has some pics you could use I'm sure.

http://www.dsmtuner.com/forums/showthread.php?t=196963

http://cgi.ebay.com/ebaymotors/2-5-...043760660QQcategoryZ38634QQrdZ1QQcmdZViewItem

http://cgi.ebay.com/ebaymotors/2-5-...043765381QQcategoryZ33742QQrdZ1QQcmdZViewItem

I also had to get a 2-2.5" elbow reducer for the turbo compressor outlet.

http://www.machv.com/elco.html

I ended up also buying 2 red silicone couplers and some clamps from ATP for the sides of my FMIC. You can do it all with just 90's, you'll have to get one more though for coming off of the throttle body, unless you have a 2.5" bend from an intake like I did.

What exactly are you confused about when it comes to the oil lines?

Here is link to one of my threads, has some pics you could use I'm sure.

http://www.dsmtuner.com/forums/showthread.php?t=196963

brings back memories...

brings back memories...