- Thread starter

- #151

twicks69

Supporting Vendor

- 4,203

- 1,663

- Mar 12, 2004

-

Milwaukee,

Wisconsin

Tim what fuel are you using?

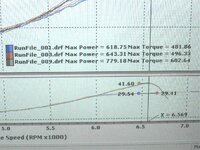

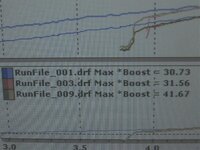

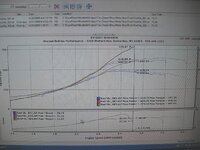

The dyno session was primarilly done on VP Q16 Race fuel.

The pump gas tune made 615AWHP or so at 30psi. It was then tuned in for VP Q16 and did 640AWHP at 30psi.