- Thread starter

- #126

Silverspyder

20+ Year Contributor

- 288

- 539

- Nov 18, 2002

-

Lakeville,

Minnesota

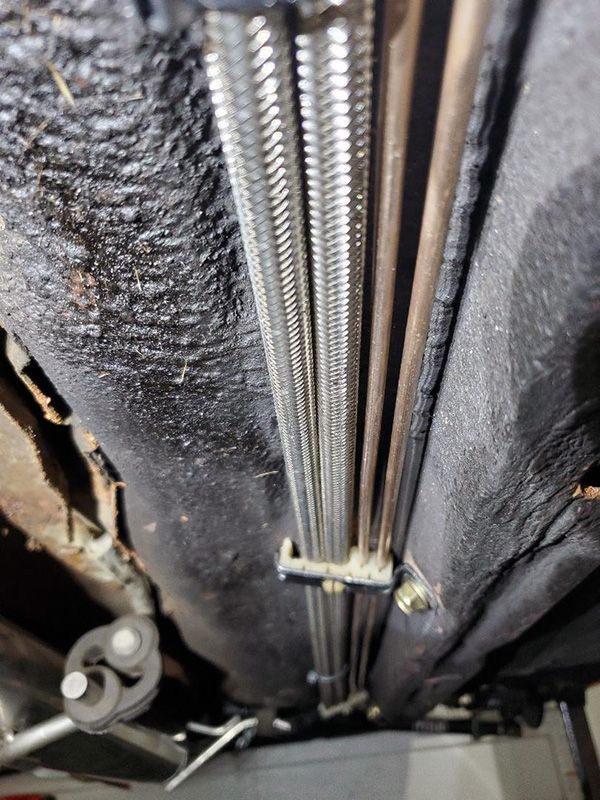

Redoing the rear brake lines was a lot easier and less troublesome than I originally thought.

I should have mentioned this before, but when starting a big brake job, here's a little trick to keep all your brake fluid from running out all over the place on you.

Anyway, got the lines run. I ran them the same route as the OEM lines. The only somewhat complicated parts were where the lines make a lot of bends to come up over the frame and into the wheel well, but still wasn't too bad with Nicopp line. All bends were done by hand. I used all steel connections and stainless steel unions. Brass would have been fine I'm sure, but I wanted steel just to make extra sure.

This flaring tool is great. Easy to make flares with the lines on the car.

Can't forget the gravel guard in the wheel wells...

I also bought an oil catch can off Amz...this one is made very well, so I got it mounted where I want it too...I'll run the lines another time.

I should have mentioned this before, but when starting a big brake job, here's a little trick to keep all your brake fluid from running out all over the place on you.

Anyway, got the lines run. I ran them the same route as the OEM lines. The only somewhat complicated parts were where the lines make a lot of bends to come up over the frame and into the wheel well, but still wasn't too bad with Nicopp line. All bends were done by hand. I used all steel connections and stainless steel unions. Brass would have been fine I'm sure, but I wanted steel just to make extra sure.

This flaring tool is great. Easy to make flares with the lines on the car.

Can't forget the gravel guard in the wheel wells...

I also bought an oil catch can off Amz...this one is made very well, so I got it mounted where I want it too...I'll run the lines another time.