99gst_racer

Moderator

- 11,981

- 1,556

- Apr 5, 2003

-

Coloma,

Michigan

I've been kicking around the idea of switching to a 1/2" head stud on my 7-bolt. The only reason would be for greater strength (more preload and clamping force) and the fact that it would be cheaper than any exotic material. Surprisingly, a 1/2" 8740 chrome moly stud is still stronger than an 11mm L19 stud.

So, this past weekend, I took and trip over to Strictly Import Motorsports and John and I did some testing with this idea. We fit a 1/2" stud on a 7-bolt block with no issues. We didn't have to remove enough material from the hole to even raise concern whether or not there would be enough left for strength. And we were able to get the nut to tighten down past the valve spring and seat without any major modifications. All in all, this seems like a sweet upgrade for either block.

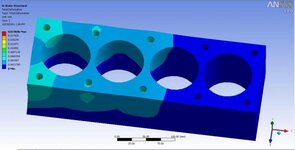

My only question is regarding deformation. I'm wondering if a larger fastener will deform the deck and/or cylinders much differently than the OE size fastener. In other words, would a hone be absolutely nessacery after switching to 1/2" studs? I'd hate to put a bunch of time and money into a junk block just for testing purposes just to answer this question, so I'm just curious is anyone has any solid opinions or experiences with doing something like this on another platform.

So, this past weekend, I took and trip over to Strictly Import Motorsports and John and I did some testing with this idea. We fit a 1/2" stud on a 7-bolt block with no issues. We didn't have to remove enough material from the hole to even raise concern whether or not there would be enough left for strength. And we were able to get the nut to tighten down past the valve spring and seat without any major modifications. All in all, this seems like a sweet upgrade for either block.

My only question is regarding deformation. I'm wondering if a larger fastener will deform the deck and/or cylinders much differently than the OE size fastener. In other words, would a hone be absolutely nessacery after switching to 1/2" studs? I'd hate to put a bunch of time and money into a junk block just for testing purposes just to answer this question, so I'm just curious is anyone has any solid opinions or experiences with doing something like this on another platform.

You must be logged in to view this image or video.

Swwwwweeeeeeeet!!!!

Swwwwweeeeeeeet!!!!