NHerron

10+ Year Contributor

- 2,776

- 58

- Nov 5, 2011

-

Missoula,

Montana

Hey guys I have 2 CEL's that's been driving me nuts. Car is 97' turbo, stock ECU, 6 bolt swapped but did not have this problem before I rebuilt the same 6 bolt. Did not mess with the emissions wiring.

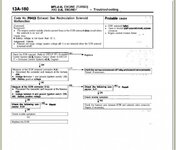

P0403 - Exhaust Gas Recirculation Circuit Malfunction

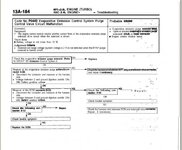

P0443 - Evaporative Emission Control System Purge Control Valve Circuit

These link's gave me a good explanation and ways to check the problem out

OBD-II Trouble Code: P0403 Exhaust Gas Recirculation Circuit Malfunction

OBD-II Trouble Code: P0443 Evaporative Emission Control System Purge Control Valve Circuit

Between those links and my FSM tech diagrams I see no reason why I still get these CEL's

Middle of firewall, behind intake manifold, I unplugged the EGR solenoid and got 75 ohms resistance. Ok good. Unplugged the EVAP solenoid and got 43 ohms resistance. Right on

Checked voltage on the disconnected connector for each solenoid and got source voltage between the pins, key on engine not running. Plugged them back in and no more ground, just 12V on each wire.

So I have source voltage between the pins unplugged, but when plugged in, the ECU disconnects ground for each solenoid.

All this tells me my solenoids are good, and power and ground wires are okay. I have yet to check ECU pins for the ground wires of each solenoid but since I got said results I don't see why I would need to.

What else is there to check? Better yet, how is the fault detected for each code? Please help, this is a new build with less than 400 miles and I'd like to rely on my CEL for things that actually matter to me

P0403 - Exhaust Gas Recirculation Circuit Malfunction

P0443 - Evaporative Emission Control System Purge Control Valve Circuit

These link's gave me a good explanation and ways to check the problem out

OBD-II Trouble Code: P0403 Exhaust Gas Recirculation Circuit Malfunction

OBD-II Trouble Code: P0443 Evaporative Emission Control System Purge Control Valve Circuit

Between those links and my FSM tech diagrams I see no reason why I still get these CEL's

Middle of firewall, behind intake manifold, I unplugged the EGR solenoid and got 75 ohms resistance. Ok good. Unplugged the EVAP solenoid and got 43 ohms resistance. Right on

Checked voltage on the disconnected connector for each solenoid and got source voltage between the pins, key on engine not running. Plugged them back in and no more ground, just 12V on each wire.

So I have source voltage between the pins unplugged, but when plugged in, the ECU disconnects ground for each solenoid.

All this tells me my solenoids are good, and power and ground wires are okay. I have yet to check ECU pins for the ground wires of each solenoid but since I got said results I don't see why I would need to.

What else is there to check? Better yet, how is the fault detected for each code? Please help, this is a new build with less than 400 miles and I'd like to rely on my CEL for things that actually matter to me

It also made me realize how much I love electronics and should persue that fantasy engineering degree...

It also made me realize how much I love electronics and should persue that fantasy engineering degree...