tommiman

15+ Year Contributor

- 273

- 5

- Aug 31, 2004

-

Vaughan,

Ontario_Canada

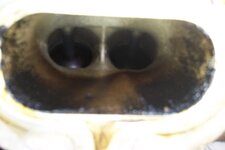

So I pulled my head for the first time after seeing white smoke at idle.

See http://www.dsmtuners.com/forums/showthread.php?t=232749 for more info.

I didnt see anything wrong with the head gasket. Maybe it wasnt sealing well. Anyhow would you more experienced DSMers have a look at the pics and give me some opinions please.

TIA

See http://www.dsmtuners.com/forums/showthread.php?t=232749 for more info.

I didnt see anything wrong with the head gasket. Maybe it wasnt sealing well. Anyhow would you more experienced DSMers have a look at the pics and give me some opinions please.

TIA

... I guess that means I won't be doing the rings... Not enough space in my garage to bring in an engine hoist. (Single car garage.) Next time I should back it in so the front faces the garage door.

... I guess that means I won't be doing the rings... Not enough space in my garage to bring in an engine hoist. (Single car garage.) Next time I should back it in so the front faces the garage door.