femmeDSM

15+ Year Contributor

- 980

- 64

- Oct 31, 2004

-

D/FW,

Texas

I am having a hell of a time trying to get my stupid fuel pump to power on.

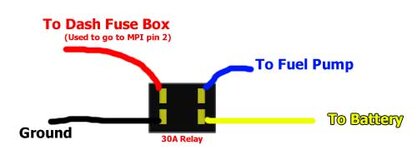

I bought the car with a botched re-wire and a bad fuel pump that was keeping the car from starting. I pulled all the old wires and re-did the fuel pump rewire correctly, and replaced the fuel pump with a Walbro 190 -- still won't turn on or prime w/ the key in ON.

The ONLY way I can get the pump to turn on is to take the 12v power wire running from the battery and touch it to the wire going to the Fuel Pump.

A list of things that I have checked/replaced so far:

- New Fuel Pump

- Re-Wire (double, triple, and quadruple checked -- everything is hooked up perfectly)

- Fuel Pump will NOT turn on using the check connector in the engine compartment.

- Tested voltage to MPI Relay, per FSM instructions. Tested out fine.

- ECU is new

- I can hear the MPI Relay click ON while cranking, and OFF a couple seconds after I try to start.

- I have good spark, and good compression, engine will turn over but will not start.

- When I revert the wiring to the stock setup (i.e. eliminate the 12v power wire from the battery, etc.) I get the same results.

- Tested voltage on the black/white power wire from pin 3 on the MPI relay -- anywhere from 9.5v to 12v (however, it was dark and cold when I did this, so I am planning on re-testing this tonight in case I got a bad ground).

I am at a loss here -- Is my only option now to trace that black/white power wire all the way from the MPI to where it connects at the FP rewire relay? Honestly, if that's my best option, I would almost rather just hook my FP up to a switch in the cabin. If all else fails, that would (SHOULD) work, right?

I am at that point where I have tested so much crap that my brain is starting to hurt.

I hope I am just overlooking something stupid, here........

Rep points will be given for ANY and ALL input!

Thanks much.

I bought the car with a botched re-wire and a bad fuel pump that was keeping the car from starting. I pulled all the old wires and re-did the fuel pump rewire correctly, and replaced the fuel pump with a Walbro 190 -- still won't turn on or prime w/ the key in ON.

The ONLY way I can get the pump to turn on is to take the 12v power wire running from the battery and touch it to the wire going to the Fuel Pump.

A list of things that I have checked/replaced so far:

- New Fuel Pump

- Re-Wire (double, triple, and quadruple checked -- everything is hooked up perfectly)

- Fuel Pump will NOT turn on using the check connector in the engine compartment.

- Tested voltage to MPI Relay, per FSM instructions. Tested out fine.

- ECU is new

- I can hear the MPI Relay click ON while cranking, and OFF a couple seconds after I try to start.

- I have good spark, and good compression, engine will turn over but will not start.

- When I revert the wiring to the stock setup (i.e. eliminate the 12v power wire from the battery, etc.) I get the same results.

- Tested voltage on the black/white power wire from pin 3 on the MPI relay -- anywhere from 9.5v to 12v (however, it was dark and cold when I did this, so I am planning on re-testing this tonight in case I got a bad ground).

I am at a loss here -- Is my only option now to trace that black/white power wire all the way from the MPI to where it connects at the FP rewire relay? Honestly, if that's my best option, I would almost rather just hook my FP up to a switch in the cabin. If all else fails, that would (SHOULD) work, right?

I am at that point where I have tested so much crap that my brain is starting to hurt.

I hope I am just overlooking something stupid, here........

Rep points will be given for ANY and ALL input!

Thanks much.

Electrical isn't my thing so I will go away now.

Electrical isn't my thing so I will go away now.  .

.