PFC_CiarlilloM

10+ Year Contributor

- 234

- 0

- May 22, 2011

-

Euclid,

Ohio

Alright so long story short, my head gasket went on me, and being unsure of the age of the timing belt I decided it was time for a timing belt/60k maintenance job as well for piece of mind.

Vehicle Info;

1996 Eclipse GSX

(7 Bolt motor)

140k w/ auto

*Supposed to be rebuilt by the previous owner of the guy I bought it off of, said to have around 40k on it, but no receipt = very skeptical*

So being my first tear down of a vehicle, I took my sweet old time tearing everything down, and labeling every bolt, connector, etc.

I put piston #1 to TDC according to the timing marks that were on the vehicle, saw the piston through the spark plug hole, verified by putting the oil dipstick down, and felt it. Removed both belts, finally removed the pulleys, and timing auto tensioner (replacing 60k/timing maintenance)

SIDE NOTE,

*Both (OEM) belts looked really good, the pulley's looked great too when wiped off, and comparing them to my OEM pulleys. So maybe the engine was really rebuilt, but timing belt components aren't good enough to make that assumption*

I kinda stumbled upon something that I thought was weird. The head bolts looked aftermarket, at first a 13mm 6pt fit just nice, and snug, but then in spun, so I went to get a 13mm 12pt (thinking they were ARP) but that was too big. A 12mm 12pt was what it ended up being.

So I assumed that they were ARP's for a 6 bolt. (Went and rechecked my oil pan.. had the dent, so its a 7 bolt) Well when I finally removed them I put my 7 bolt ARPs in the thread and they fit nice and perfect, also the bolts that came out didnt have "ARP" stamped anywhere on it. So they weren't 6 bolt 12mm ARP's.

After what seemed like forever, I finally got everything removed, and prepped to pull the head... but it wouldn't pull up..... Damn intake manifold bracket, it will get you every time . It was a PITA to remove and its definitely not going back in. (P.O said the owner before him rebuilt the motor *supposed to be around 40k on the rebuild*... was kinda hoping he removed it but I guess not)

. It was a PITA to remove and its definitely not going back in. (P.O said the owner before him rebuilt the motor *supposed to be around 40k on the rebuild*... was kinda hoping he removed it but I guess not)

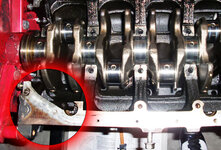

So I finally got the head off, I'm not sure how the head gasket would look being my first pull, and just started working on cars, but it didn't appear to look great in my eyes. The cylinder walls looked really good, no scoring, and it looked like I could see my reflection in them. The pistons just looked like they had some carbon build up, but somehow piston #1 isnt at TDC anymore. The all appear midstroke.

From here I am cleaning everything up to put on my Felpro composite (Part No. HS 9627 PT-3) head gasket, ARP headstuds, gates water pump, and OEM timing belt/components using @BogusSVO's method's (http://www.dsmtuners.com/forums/cylinder-head-short-block/413772-how-clean-head-gasket-surface.html)

(http://www.dsmtuners.com/forums/new...r-how-clean-block-deck-pistons-installed.html)

Just wanted to see what you guys think just going off the pictures I attached, as well as any helpful tips or advice.

Vehicle Info;

1996 Eclipse GSX

(7 Bolt motor)

140k w/ auto

*Supposed to be rebuilt by the previous owner of the guy I bought it off of, said to have around 40k on it, but no receipt = very skeptical*

So being my first tear down of a vehicle, I took my sweet old time tearing everything down, and labeling every bolt, connector, etc.

I put piston #1 to TDC according to the timing marks that were on the vehicle, saw the piston through the spark plug hole, verified by putting the oil dipstick down, and felt it. Removed both belts, finally removed the pulleys, and timing auto tensioner (replacing 60k/timing maintenance)

SIDE NOTE,

*Both (OEM) belts looked really good, the pulley's looked great too when wiped off, and comparing them to my OEM pulleys. So maybe the engine was really rebuilt, but timing belt components aren't good enough to make that assumption*

I kinda stumbled upon something that I thought was weird. The head bolts looked aftermarket, at first a 13mm 6pt fit just nice, and snug, but then in spun, so I went to get a 13mm 12pt (thinking they were ARP) but that was too big. A 12mm 12pt was what it ended up being.

So I assumed that they were ARP's for a 6 bolt. (Went and rechecked my oil pan.. had the dent, so its a 7 bolt) Well when I finally removed them I put my 7 bolt ARPs in the thread and they fit nice and perfect, also the bolts that came out didnt have "ARP" stamped anywhere on it. So they weren't 6 bolt 12mm ARP's.

After what seemed like forever, I finally got everything removed, and prepped to pull the head... but it wouldn't pull up..... Damn intake manifold bracket, it will get you every time

. It was a PITA to remove and its definitely not going back in. (P.O said the owner before him rebuilt the motor *supposed to be around 40k on the rebuild*... was kinda hoping he removed it but I guess not)

. It was a PITA to remove and its definitely not going back in. (P.O said the owner before him rebuilt the motor *supposed to be around 40k on the rebuild*... was kinda hoping he removed it but I guess not)So I finally got the head off, I'm not sure how the head gasket would look being my first pull, and just started working on cars, but it didn't appear to look great in my eyes. The cylinder walls looked really good, no scoring, and it looked like I could see my reflection in them. The pistons just looked like they had some carbon build up, but somehow piston #1 isnt at TDC anymore. The all appear midstroke.

From here I am cleaning everything up to put on my Felpro composite (Part No. HS 9627 PT-3) head gasket, ARP headstuds, gates water pump, and OEM timing belt/components using @BogusSVO's method's (http://www.dsmtuners.com/forums/cylinder-head-short-block/413772-how-clean-head-gasket-surface.html)

(http://www.dsmtuners.com/forums/new...r-how-clean-block-deck-pistons-installed.html)

Just wanted to see what you guys think just going off the pictures I attached, as well as any helpful tips or advice.

Attachments

Last edited:

, its where the oil pan meets the block surface. pic posted. Sorry for the confusion, its been a minute since I got deep into the engine stuff...

, its where the oil pan meets the block surface. pic posted. Sorry for the confusion, its been a minute since I got deep into the engine stuff...