danl

20+ Year Contributor

- 886

- 274

- Apr 8, 2002

-

Severn,

Maryland

I am posting this for a friend who has been trying to fix this issue for over a year. I will provide cliffnotes at the end if you don't want to read through the whole next paragraph.

The story starts with a 1990 GSX 5 speed that had no vibration problems. We then put a DSS 3.5" driveshaft in the car and it was fine. Then the first track day he snapped the cross shaft on the stock rear section that you reuse with the DSS shaft. It beat around in the car real good as the tires spun and the broken driveshaft was wacking the subframe pretty good. So then we put a used rear section in the car and it had a horrible vibration at 30-40mph and did not go away with speed. I then let him borrow a complete OEM driveshaft from my 91 AWD 5 speed that was under construction. The car ran fine, cut some 1.4 sixtey foots and no vibration. I then needed my driveshaft back so he sent his DSS shaft to a local driveshaft shop to be rebalanced as we assumed it was somehow damaged. It was rebalanced, returned, and put on the car with an unknown condition rear section. The whole assembly vibrated. Another rear section of unknown condition was put on, the whole assembly vibrates. He has tried 3 different TX cases even though the one was fine with my driveshaft on the car. With the car on jackstands in the air he can not see the driveshaft vibrating anywhere. We are at wits end on this one as he is putting a THIRD rear section in the car now. I'm going to start putting these driveshafts on my car to see if the problem follows his car or if it is indeed the driveshafts. I do not believe the problem is the tx case, any part of the actual driveshaft, or the rear end. What else could cause this problem? The carrier bearings are filled on these shafts.

CN: 1g AWD broke driveshaft and can't seem to piece together a driveshaft that won't vibrate. Have tried multiple driveshafts and tx cases.

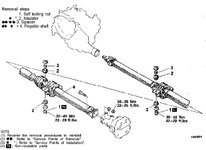

Here is a picture of the driveshaft assembly so we are all on the same page.

The story starts with a 1990 GSX 5 speed that had no vibration problems. We then put a DSS 3.5" driveshaft in the car and it was fine. Then the first track day he snapped the cross shaft on the stock rear section that you reuse with the DSS shaft. It beat around in the car real good as the tires spun and the broken driveshaft was wacking the subframe pretty good. So then we put a used rear section in the car and it had a horrible vibration at 30-40mph and did not go away with speed. I then let him borrow a complete OEM driveshaft from my 91 AWD 5 speed that was under construction. The car ran fine, cut some 1.4 sixtey foots and no vibration. I then needed my driveshaft back so he sent his DSS shaft to a local driveshaft shop to be rebalanced as we assumed it was somehow damaged. It was rebalanced, returned, and put on the car with an unknown condition rear section. The whole assembly vibrated. Another rear section of unknown condition was put on, the whole assembly vibrates. He has tried 3 different TX cases even though the one was fine with my driveshaft on the car. With the car on jackstands in the air he can not see the driveshaft vibrating anywhere. We are at wits end on this one as he is putting a THIRD rear section in the car now. I'm going to start putting these driveshafts on my car to see if the problem follows his car or if it is indeed the driveshafts. I do not believe the problem is the tx case, any part of the actual driveshaft, or the rear end. What else could cause this problem? The carrier bearings are filled on these shafts.

CN: 1g AWD broke driveshaft and can't seem to piece together a driveshaft that won't vibrate. Have tried multiple driveshafts and tx cases.

Here is a picture of the driveshaft assembly so we are all on the same page.