RossY

20+ Year Contributor

- 627

- 2

- Sep 27, 2002

-

Canton,

Ohio

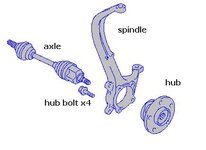

Ok, so my axle is stuck in my hub. i have tried everything from pb blaster soaking over night, heat, sledge, and even a press. This thing is NOT coming off.

I even broke down and took it to a mechanic who was also unable to get it off. My question now is what else am i going to have to break, remove and replace to get my axle out and how should i go about doing this?

I even broke down and took it to a mechanic who was also unable to get it off. My question now is what else am i going to have to break, remove and replace to get my axle out and how should i go about doing this?

.

.