compression

15+ Year Contributor

- 1,433

- 11

- Dec 9, 2004

-

vero beach,

Florida

I havent gotten any email replies from daniel. So ill let you know as soon as i do.

Thr helmet brand is, rhino welding helmets. And ive been using it on the same amperage for nearly a week allready. First time i ever had an issue was last night.

Is the 9 the smallest torch?

Thr helmet brand is, rhino welding helmets. And ive been using it on the same amperage for nearly a week allready. First time i ever had an issue was last night.

Is the 9 the smallest torch?

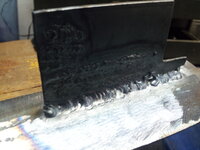

. Im doing a cert test in week and a half for a open groove vertical up with 6010 root pass and 7018 filler and cover. As well as a dual shield single bevel with backing strip vertical up. Both on 3/8 plate. not sure ill pass the stick one

. Im doing a cert test in week and a half for a open groove vertical up with 6010 root pass and 7018 filler and cover. As well as a dual shield single bevel with backing strip vertical up. Both on 3/8 plate. not sure ill pass the stick one