Zerocygnal

20+ Year Contributor

- 641

- 1

- Jul 1, 2002

-

Springfield,

Ohio

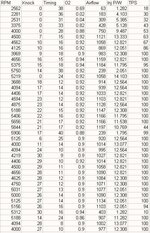

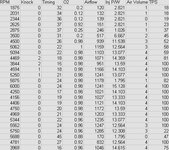

I'm pulling a massive knock count at any kind of acceleration over 25%. After logging I saw that my Injector Duty Cycle would never go over 40%, and the pulse width was always below 13.00 (should be 22.00 or more at WOT). I definately have a fuel issue..my question is where? Is this a faulty pressure regulator? Would that even effect the electronic readings of the injectors?

Thanks...would like to have my DSM running right.

This knock is killing my timing.

Thanks...would like to have my DSM running right.

This knock is killing my timing.

.

.