GSXlaunch

15+ Year Contributor

- 392

- 0

- Sep 3, 2003

-

TexasUS

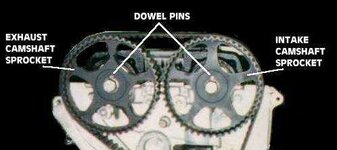

I just installed the head on my 91GSX this morning. I am pretty sure everything was at tdc and everything was lined up. How can it be that all the lobes on both cams are exactly in the same position? It just seems weird to me. I am thinking the way the valves are located in the head the intake and exhaust vavles will still open at different times. Is this right or did I do something wrong. Here is the pic...

http://f2.pg.photos.yahoo.com/ph/leche1103/vwp?.dir=/1991+GSX&.dnm=cam+lobes.jpg&.view=t

Secondly, assuming everthing is okay thus far, can I manualy turn the crank a few times before starting her up to make sure no valves will hit??? or is there an easier way to ensure I will not bend any valves? I used arp head studs and torqued them down to 85lbs....thanks for the help in advance.

TT

http://f2.pg.photos.yahoo.com/ph/leche1103/vwp?.dir=/1991+GSX&.dnm=cam+lobes.jpg&.view=t

Secondly, assuming everthing is okay thus far, can I manualy turn the crank a few times before starting her up to make sure no valves will hit??? or is there an easier way to ensure I will not bend any valves? I used arp head studs and torqued them down to 85lbs....thanks for the help in advance.

TT

no biggy. I was just wonderin cuz they worked at 6 for me.

no biggy. I was just wonderin cuz they worked at 6 for me.