gabytech

15+ Year Contributor

- 526

- 11

- Nov 19, 2007

-

Daytona,

Florida

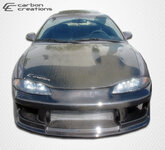

Trying to get a carbon fiber manufacturer to make 2G custom carbon fiber exterior parts like a 2GB front bumper, side skirt, and rear bumper. Just checking if there is a good interest from our DSM community to check if we can arrange a group buy.. NOTE: I'm NOT organizing a group buy, Im just checking the community interest as to get the carbon fiber manufacturer on board and have them organize a group buy...