GreddySpyder

20+ Year Contributor

- 415

- 0

- Oct 21, 2002

-

Alabama

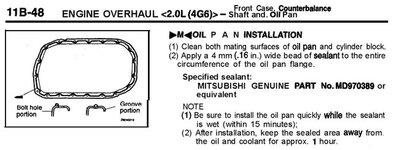

I changed my leaky oil pan gasket not long ago and it is still leaking. I used red rtv as the gasket and ran a nice continuous bead around the whole pan making a circle around each bolt hole. I think the two mistakes I made were not waiting for the RTV to dry before putting the pan back on, and I think I tightened the bolts too much ( I ended up breaking one of them).

I'm gonna buy a torque wrench and make sure they are right this time... how much torque do the pan bolts require? How long should I let the RTV dry this time before putting the pan back on?

I'm gonna buy a torque wrench and make sure they are right this time... how much torque do the pan bolts require? How long should I let the RTV dry this time before putting the pan back on?