MrNeedles

10+ Year Contributor

- 79

- 0

- Jan 17, 2009

-

Chicago,

Illinois

Hey,

Today, a buddy and I went on a tuning run around town. When we got back to my house, we turned the car off for a bit. I had to move it further up my driveway, so I started her back up and put her in drive. There was a slight feeling on engagement but it just would not move. It inched a little bit at low rpm but not much.

Earlier in the day I put on a 24,000 gvw trans cooler because my previous one was leaking. Could low ATF cause this to happen? I haven't checked it yet becuause it was dark when we got back.

Reverse seems to work fine. The car idles and rev perfectly fine. The only thing I noticed was that it was slipping slightly at full throttle and shifting a bit odd but still running strong.

Building a race car just seems like for every one step forward, there's 2 steps back.

Today, a buddy and I went on a tuning run around town. When we got back to my house, we turned the car off for a bit. I had to move it further up my driveway, so I started her back up and put her in drive. There was a slight feeling on engagement but it just would not move. It inched a little bit at low rpm but not much.

Earlier in the day I put on a 24,000 gvw trans cooler because my previous one was leaking. Could low ATF cause this to happen? I haven't checked it yet becuause it was dark when we got back.

Reverse seems to work fine. The car idles and rev perfectly fine. The only thing I noticed was that it was slipping slightly at full throttle and shifting a bit odd but still running strong.

Building a race car just seems like for every one step forward, there's 2 steps back.

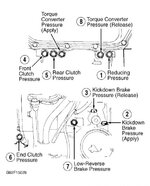

and i know. in my rebuild trend ill cover allot of this for everybody. in my opinion if you can rebuild a engine you can rebuild a auto. they seem intimidation but they really not that bad till u get to the kind i posted a pic of

and i know. in my rebuild trend ill cover allot of this for everybody. in my opinion if you can rebuild a engine you can rebuild a auto. they seem intimidation but they really not that bad till u get to the kind i posted a pic of