bastarddsm

20+ Year Contributor

- 5,643

- 1,478

- Aug 26, 2003

-

Mendota,

Illinois

So, I've been toying with what to do with my fuel system now that I'm in the area where a 255 inline won't cut it anymore. I wanted to see what the stock fuel system is actually capable of. I really didn't want to deal with the hassle of running a -6 or 8 up front and using a aftermarket filter. That and I have a nice setup for running my dual rails.

So I put together a down 'n durty test rig. Basically it's an old russel (think Holley Red) fuel pump flowing into a ball-valve with a pressure gauge after it, then connected to the system I wanted to test.

The pump was capable of flowing 8.2l/min, with negligable pressure drop, with nothing connected to it.

Connecting a 3' piece of -6, the flow stayed at 8.2l/min, but had 1psi drop.

Next I connected a brand new WIX replacement filter to the -6 hose with a 12" piece of 5/16" line.

8l/min @ 4psi. Clearly it flows very good, enough for 2000cc injectors! Way better than I expected, and would flow more with more pressure drop, the pump was maxed out in this instance.

Then I connected one stock "filter to rail line" 6.8l/min @ 8psi. The stock line is well known as a restriction, but IMHO, not worth upgrading.

Next I used my "extended banjo bolt" to install a second "filter to rail line", as I run on my car with 2 fuel rails. It flows 7l/min @ 5psi.

Finally I added about 8' of 5/16" hardline to simulate the factory line.

6.8l/min @ 8.5psi Obviously I won't be upgrading this. This is enough flow for like 800whp on E85 with only 8.5psi of drop. Meaning if you run 43psi base fuel pressure, and you have 35psi boost, the pressure your pump will see is 86.5psi, which is well within 255's in series or an 044's reach.

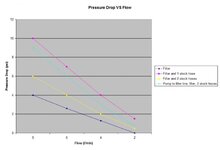

I took way more data than presented here, but to make it easier to compare, I fit a curve to each data set, then plotted it to be able to see the pressure drop of each system at a given flow rate.

So in conclusion. If your going to upgrade fuel system, I'd recommend doing the filter to rail line only unless you run a dual setup like mine. If you must upgrade the filter and pump to filter line, I'd suggest going to a -8 to get any real gain.

So I put together a down 'n durty test rig. Basically it's an old russel (think Holley Red) fuel pump flowing into a ball-valve with a pressure gauge after it, then connected to the system I wanted to test.

The pump was capable of flowing 8.2l/min, with negligable pressure drop, with nothing connected to it.

Connecting a 3' piece of -6, the flow stayed at 8.2l/min, but had 1psi drop.

Next I connected a brand new WIX replacement filter to the -6 hose with a 12" piece of 5/16" line.

8l/min @ 4psi. Clearly it flows very good, enough for 2000cc injectors! Way better than I expected, and would flow more with more pressure drop, the pump was maxed out in this instance.

Then I connected one stock "filter to rail line" 6.8l/min @ 8psi. The stock line is well known as a restriction, but IMHO, not worth upgrading.

Next I used my "extended banjo bolt" to install a second "filter to rail line", as I run on my car with 2 fuel rails. It flows 7l/min @ 5psi.

Finally I added about 8' of 5/16" hardline to simulate the factory line.

6.8l/min @ 8.5psi Obviously I won't be upgrading this. This is enough flow for like 800whp on E85 with only 8.5psi of drop. Meaning if you run 43psi base fuel pressure, and you have 35psi boost, the pressure your pump will see is 86.5psi, which is well within 255's in series or an 044's reach.

I took way more data than presented here, but to make it easier to compare, I fit a curve to each data set, then plotted it to be able to see the pressure drop of each system at a given flow rate.

So in conclusion. If your going to upgrade fuel system, I'd recommend doing the filter to rail line only unless you run a dual setup like mine. If you must upgrade the filter and pump to filter line, I'd suggest going to a -8 to get any real gain.

).

).

.

.