jpmxrider489

10+ Year Contributor

- 2,410

- 146

- Apr 4, 2010

-

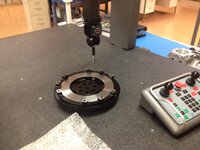

pittsburgh,

Pennsylvania

I had replaced my clutch a year or so ago and only driven the car roughly 5000 miles. The flywheel is a act streetlite, clutch is a act 2600 with a street disk. I have only been to the track once since this clutch install. I did purchase these items used but with extremely low miles (guy gave me receipt of purchase). I did have my flywheel machined to the correct step height. I purchased a new oem throw out bearing and pivot ball. I didn't replace the fork but it didn't look worn. I believe I read somewhere that if I rev the engine with the clutch in, and if the car moves then I should of shimmed the pivot ball? My car does move when revving high, above my launch limit. Now based on these pictures, is this unusual wear of the flywheel, clutch, and disk? Should I shim the pivot ball now? Also this is on a 20g at 25psi on e85.

I blew my motor and in the process of reinstalling the new one. Motor is currently out.

I blew my motor and in the process of reinstalling the new one. Motor is currently out.