mnetwork

15+ Year Contributor

- 1,017

- 2

- Feb 25, 2006

-

New Milford,

New_Jersey

I'm looking into buying BlueMax 1450cc injectors and I was wondering how tuning is on these. I am seeing mixed answers and I would like some input from people who have used or are currently using these with DSMLink. How is the driveability on them? Any issues?

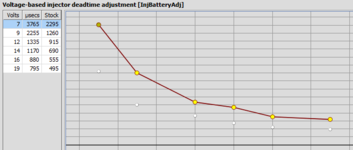

) start blindly assuming that deadtime is the cause of fuel trim error. Personally, I'd much rather just pay Tom or Jens a few $$ and plug in the numbers they tell me to for deadtime, and assume fuel trim error is the result of airflow calibration issues... at least to start with.

) start blindly assuming that deadtime is the cause of fuel trim error. Personally, I'd much rather just pay Tom or Jens a few $$ and plug in the numbers they tell me to for deadtime, and assume fuel trim error is the result of airflow calibration issues... at least to start with.