jpmxrider489

10+ Year Contributor

- 2,411

- 146

- Apr 4, 2010

-

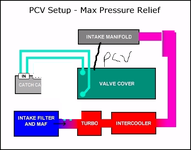

pittsburgh,

Pennsylvania

So I have the jmfab catch can and fp intake pipe. Now the problem I am having is under boost oil will spray from the dipstick tube. But the dipstick is not popping out. I do not have it recirculated back into the intake pipe but I did take the breather off the can and sealed it off. Not my lines for the can are coming off the top of the valve cover. I am still using the factory pcv. Would recirculating it back into the intake pipe solve this? I don't want to spring the dipstick down because that isn't fixing the problem. Also my boost is set at 17. I can tap my intake pipe if that will solve the problem. I read calans thread on it multiple times and im having a hard time finding what setup is best for me. I do want to keep the fittings on top of the cover and will get rid of the pcv if that will help.