- Thread starter

- #201

Atuca

Supporting Member

- 1,140

- 292

- Jan 6, 2007

-

Central Valley,

California

that is correct, except the last layer. The lay up resin "dries" to be tacky to the touch. To get rid of the tacky feeling, you can add wax or pva to the last batch of resin, and when that dries, it hardens to a smooth "sandable" final layer. I don't think sanding the backside will be much use, but it just gives it a smooth finish compared to the tacky to the touch.

As I understand it, some resins have wax in them already and dry smooth, but the Vinyl Ester needs it. This is coming from the sales rep at US composites.

Is it your opinion that is completely bogus? I only know what you, the sale rep, and some research has told me; nothing from experience. I used the cheap crap from home depot to make the plugs.

As I understand it, some resins have wax in them already and dry smooth, but the Vinyl Ester needs it. This is coming from the sales rep at US composites.

Is it your opinion that is completely bogus? I only know what you, the sale rep, and some research has told me; nothing from experience. I used the cheap crap from home depot to make the plugs.

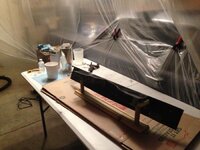

! its good to have a large unfinished basement across the hall

! its good to have a large unfinished basement across the hall