mikyrc

15+ Year Contributor

- 197

- 4

- Nov 18, 2003

-

Spain,

Europe

Hey guys I'm a bit worried. I thought that on the 1G I would be able to run 20-22psi on pump gas but it seems not.

I'm using stock 7.8:1 pistons, Evo VIII FMIC, no coolant lines on the TB, anti temp gasket between intake mani and head, 2.5" IC piping, 2.75-3" exhaust, BR7es plugs, a plate that avoids engine bay hot air to get sucked by the air filter and using 98 octane gas wich should be like 91-93 octane in USA.

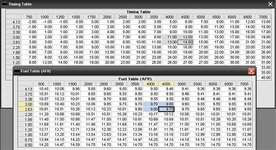

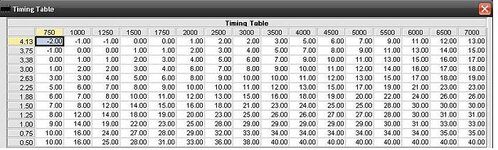

I attach the timing map and fuel map i'm using (they're the extended version ones)

Usually I'm getting knock at 4-4.5k on the 2.63-3.00 g/rev range. around 10 counts and then it goes away at around 5.5k but timing drops a bit too (to 9º at 5k if i remember correctly).

(You can see the attached image 5 posts below, Imageshack deleted the original image I don't know why)

As You can see the A/F is already pretty rich, so it's not a lean problem.

If I add a bit more fuel with the SAFC the knock dissapear unless I rise the boost again over 18psi.

Any ideas of what's wrong? Or is that completelly normal?

I thought I could run more boos easily with my setup but it seems not.

Are the timing table correct on that 2.63-3.00 g/rev 3k-7.5krpm range?

I'm using stock 7.8:1 pistons, Evo VIII FMIC, no coolant lines on the TB, anti temp gasket between intake mani and head, 2.5" IC piping, 2.75-3" exhaust, BR7es plugs, a plate that avoids engine bay hot air to get sucked by the air filter and using 98 octane gas wich should be like 91-93 octane in USA.

I attach the timing map and fuel map i'm using (they're the extended version ones)

Usually I'm getting knock at 4-4.5k on the 2.63-3.00 g/rev range. around 10 counts and then it goes away at around 5.5k but timing drops a bit too (to 9º at 5k if i remember correctly).

(You can see the attached image 5 posts below, Imageshack deleted the original image I don't know why)

As You can see the A/F is already pretty rich, so it's not a lean problem.

If I add a bit more fuel with the SAFC the knock dissapear unless I rise the boost again over 18psi.

Any ideas of what's wrong? Or is that completelly normal?

I thought I could run more boos easily with my setup but it seems not.

Are the timing table correct on that 2.63-3.00 g/rev 3k-7.5krpm range?

I guess I dont understand the numbers in the left clum. I guess they are load but they lok different than the way we have ours setup.

I guess I dont understand the numbers in the left clum. I guess they are load but they lok different than the way we have ours setup.