Hiitman

15+ Year Contributor

- 482

- 3

- May 12, 2004

-

Colorado Spring,

Colorado

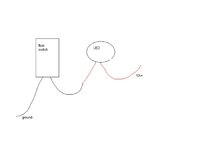

Off subject but this is for turboglenn. Sorry I don't know how to send pics in PMs. The first pic is of the wiring and the old MAP sensor (still in place but disabled under DSMlink Misc). The second pic is of the GM sensor T'd off of the BOV.