STARION

20+ Year Contributor

- 193

- 0

- May 30, 2002

-

Nova,

D.C.

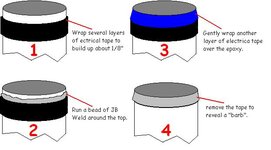

hey, well, I am beading my IC pipes (using JB weld) and am wondering if it matters hugely how thick the beads are. I don't want them to be so big that I have to wrestle to put on the silicone couplings. I'm thinking that more than anything, just having a bead will help, and making it taller will not net a huge gain. However, I also want them to hold boost, just wondering if anybody has any insights