DSM4LIFE-AWD

10+ Year Contributor

- 322

- 10

- Aug 6, 2009

-

Trois-Rivieres,

QC_Canada

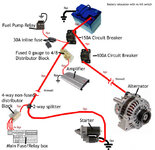

After reading and searching all day long I came up with this draw.

I still dont know if its the way to go ... Some threads say that you need to put an other 80 amp fuse near the starter ? Some say that the circuit breaker need to be after the switch ?

Well I used the diagram that came with the moroso kill-switch to do this picture and I want to know if I miss something before I put fire in my dsm ...

Thanks

You must be logged in to view this image or video.

I still dont know if its the way to go ... Some threads say that you need to put an other 80 amp fuse near the starter ? Some say that the circuit breaker need to be after the switch ?

Well I used the diagram that came with the moroso kill-switch to do this picture and I want to know if I miss something before I put fire in my dsm ...

Thanks