- Thread starter

- #51

jakk220

10+ Year Contributor

- 1,319

- 312

- Nov 13, 2010

-

Akron,

Ohio

Post a good 3rd gear pull and I'll tweak your VE table, and set global where it should be. You can then do a pull on that tune and see where you're at. I also need a shot of your injecor flow rates, and the voltages if you have them.

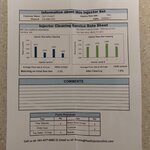

Here is the injector flow chart. Getting ready to go get the log now.

.

.