DannyE

Proven Member

- 105

- 21

- Dec 2, 2016

-

Martinsburg,

West_Virginia

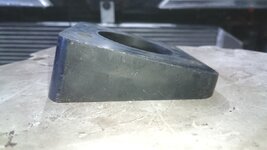

Hey fellas, I have a slight issue with my new turbo and manifold. The problem I’m having is the t3 10cm turbine housing is contacting the block right at the balance shaft bulge. The turbo is a hahn s20g and the manifold is an fp, also the turbo has the adapter for it to work on the dsm manifolds, I’m not sure if even a manifold spacer will work seeing I have about a 1/4” gap between the manifold and head. I mean, I see people say it’s a bolt up affair? I would like to know how that is, yeah it’s a bolt up job maybe if you can make a custom manifold. Any info on this would be appreciated.

I thought they came surfaced and ready to go. Well luckily for me I rebuilt dirt bikes and atvs so I already have a large granite lapping stone and wet paper. To be honest I don’t want to sit there lapping the thing for hours seeing it’s made from steel.

I thought they came surfaced and ready to go. Well luckily for me I rebuilt dirt bikes and atvs so I already have a large granite lapping stone and wet paper. To be honest I don’t want to sit there lapping the thing for hours seeing it’s made from steel.