Corey N

Probationary Member

- 8

- 1

- Apr 6, 2013

-

Milwaukie,

Oregon

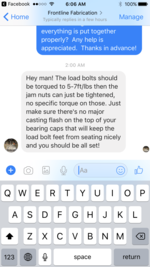

Installing a Frontline Fab rear diff cover on my 2g in a few days and am hoping to gather more info regarding the load bolts that put pre-tension on the bearing caps and adjusting/setting them properly. I've done some google searching with no luck and got no response when I emailed Frontline Fab. Is there a proper torque specification or some kind of measurement I take when installing it to make sure everything is put together properly? Any help is appreciated. Thanks in advance!

You must be logged in to view this image or video.