fredom dsm

15+ Year Contributor

- 321

- 48

- Jan 31, 2006

-

Denton,

Texas

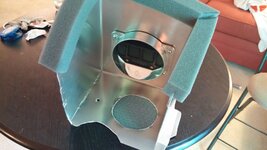

Hello guys! I build this heat shield out of cardboard and then MDF but I want the final product to be made out of aluminum. Is there anyone here that can take on this task for me. Please PM me if anyone is willing to help me out.

Thanks.

Thanks.