my1st2genGSX

Proven Member

- 141

- 10

- Aug 4, 2016

-

San Antonio,

Texas

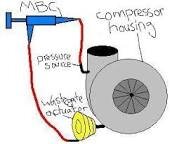

so, my gsx has been down just got it back up and running. I've done most of the maintenance: timing belt, water pump, checked spark plugs etc. question is before it went down (due to the crank position sensor) my car wouldn't boost over 13lbs. It appears to have an adjustable internal wastegate...not sure if that is accurate. I do have a turboxs mbc, but I still can't get nothing over 13lbs. I want to make more with what I have already on the car...I haven't checked the injectors yet so I can't tell you what they are, they are black-which with enough reading on here I think they are stock 450s. And also when I'm at wot my afr is reading really rich. So in my mind is think more boost to equal out the afrs. What is your in put by chance? I have been also posting on the Turbo section as well.

. Serves it's purpose though

. Serves it's purpose though

I will be trying this on my next day off and installing a smaller serpentine belt....

I will be trying this on my next day off and installing a smaller serpentine belt....