DsmDanny9

Probationary Member

- 26

- 1

- Feb 22, 2017

-

Selinsgrove,

Pennsylvania

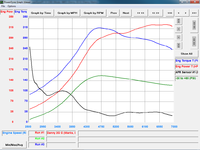

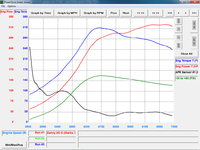

I'm starting this thread as I am going awd this week. I'll be sure to post threads of each section of the AWD swap as its coming along. Me and my best friends have already swapped a 98 spyder that had a built bottom end. It had an hx35 that was maxed out at 32.6psi. It made about 530 awhp on e85. My build won't be that crazy from the get go but over time I plan to get it to about that if not a bit more.

My car has some mods and for the most part I'm not changing anything aside from my awd swap. About 2 months ago I had a blown t25 so I upgraded my full turbo setup. Tubular mani, evo 3 16g with a dumped 02 housing. When I did that I also put my aem wideband in, but I plan to swap it out for an innovate as its more user friendly with DSMLink. When I did this I also installed a vrsf core. It's a bit overkill now, but like I said I plan to go higher in power so it'll be needed in time. I put my walbro 255 pump in as well as my tank to rail kit an aeromotive AFPR. here's a few pictures from that process as well as my awd supplies set out and ready to go.

My plan of action is as follows

1. Drop the fwd rear subframe, tank and filler neck.

2. Install AWD subframe, rear diff, tank, filler neck

3. Pull engine to swap flywheel. While I'm doing this I'm putting a southbend clutch setup as well as doing some preventive maintenance by putting in a new throw out bearing, pivot ball and a forged clutch fork

4. Weld the driveshaft brackets into place

5. Install t-case

6. Install driveshaft

These steps are obviously a vague outline of what's happening and the posts to each steps will be much more detailed and have plenty of pictures so it's easy to follow. I'm the type of person to who learns better when I can do, but the next best thing to that is plenty of pictures.

My car has some mods and for the most part I'm not changing anything aside from my awd swap. About 2 months ago I had a blown t25 so I upgraded my full turbo setup. Tubular mani, evo 3 16g with a dumped 02 housing. When I did that I also put my aem wideband in, but I plan to swap it out for an innovate as its more user friendly with DSMLink. When I did this I also installed a vrsf core. It's a bit overkill now, but like I said I plan to go higher in power so it'll be needed in time. I put my walbro 255 pump in as well as my tank to rail kit an aeromotive AFPR. here's a few pictures from that process as well as my awd supplies set out and ready to go.

My plan of action is as follows

1. Drop the fwd rear subframe, tank and filler neck.

2. Install AWD subframe, rear diff, tank, filler neck

3. Pull engine to swap flywheel. While I'm doing this I'm putting a southbend clutch setup as well as doing some preventive maintenance by putting in a new throw out bearing, pivot ball and a forged clutch fork

4. Weld the driveshaft brackets into place

5. Install t-case

6. Install driveshaft

These steps are obviously a vague outline of what's happening and the posts to each steps will be much more detailed and have plenty of pictures so it's easy to follow. I'm the type of person to who learns better when I can do, but the next best thing to that is plenty of pictures.

. I started working from back to front with mocking the tank up and welding the bolts into place where they need to be. Here's some pics of every step I just spoke about as well as my engine bay that's being prepped for paint.

. I started working from back to front with mocking the tank up and welding the bolts into place where they need to be. Here's some pics of every step I just spoke about as well as my engine bay that's being prepped for paint.