- Thread starter

- #251

keltalon

Supporting VIP

- 3,474

- 959

- Jun 29, 2003

-

Luthersville Ga, Atlanta,

Georgia

Yeah it's been a while since I started this awd trek I am very excited and looking forward to all the sleepless ncan wait to here your comments on AWD

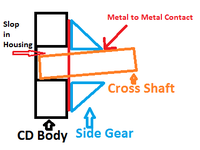

Don't worry my tmz super duty shaft will be here tomorrow. After all my reading I definitely would not have used the stocker. This goes also for the t case and axles.Well, it will be center diff soup very quickly. That's a machined down cross shaft, and its probably loose hell in the case. It'll be galled up in a hurry.

Oh forgot to mention the gears of the center diff, TMZ cross shaft, center diff housing and all the washers will be cryo and wpc treated. Just something I just want to get done that's all

.

.