Kdouglas89

Proven Member

- 436

- 11

- Jul 8, 2013

-

Davenport,

Iowa

Car is a GSX.

I just got done putting a new control arm on front driver side due to ball joint going bad. Was spinning the wheel and noticed that there was a loud noise like gears where hittin each other coming from inside the brake area.

I also noticed with front side jacked up, if I spin drivers side wheel, passenger side does not spin with it. Should this happen? Noise is only happening from drivers side, passenger side is quite.

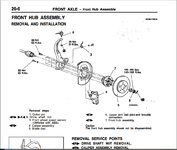

I was looking through service manual with no luck, and I am clueless on suspension issues.

Edit: Narrowed it down to axle is not connected to drivers side hub? What would cause the axle to spin everything but not drivers side tire?

I just got done putting a new control arm on front driver side due to ball joint going bad. Was spinning the wheel and noticed that there was a loud noise like gears where hittin each other coming from inside the brake area.

I also noticed with front side jacked up, if I spin drivers side wheel, passenger side does not spin with it. Should this happen? Noise is only happening from drivers side, passenger side is quite.

I was looking through service manual with no luck, and I am clueless on suspension issues.

Edit: Narrowed it down to axle is not connected to drivers side hub? What would cause the axle to spin everything but not drivers side tire?

Last edited: